Screening

Which has a larger opening, a 40 mesh screen or 20 mesh screen? What’s the micron equivalent for a #325 US test sieve? What’s the difference between a 60 TBC and a 60 Market Grade screen? Which has more open area, a 16 Mill Grade or 16 Market Grade? Get the answers to these questions and more with our easy to use Screen Mesh Conversion Chart.

Download it now!

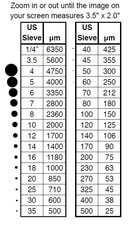

What does a 20 mesh particle look like? See for yourself with our Particle Size Scale. Just download the file and zoom in or out on your screen until it is business card size.

SWECO Round Separators are ideal for separating solids from liquids or segregating dry materials into various particle sizes. Proven design, long screen life, and easy screen changes are features that have made this device the most versatile and popular screening machine in the world.

SWECO Rectangular Separators deliver capacities higher than what can be achieved on traditional round separators. Available with linear, round, or elliptical motion, these separators offer features such as zero grit bypass made possible through the use of innovative inflatable seals.

The SWECO ATLAS Gyratory Sifter is our biggest sifter yet, offering high capacity screening in a low maintenance, operator friendly design. The horizontal, uniform gyratory motion of the ATLAS provides the highest performance per square foot of screen area available today. This means uniform material spreading, exceptional screen cleaning and sharper separations all leading to unparalleled capacity ratings.

Ideal for a wide range of industries including chemical, food, plastics, agriculture and minerals, the ATLAS is available with:

- 33 versatile configurations

- up to 12 screens

- 32 ft² - 792 ft² of screen area

- 2-5 product fractions

Additionally, each ATLAS model integrates SWECO’s patented QuickChange™ technology, allowing for 1 minute screen changes that can be performed from either end of the machine. Additional benefits include a unique high performance feed box, zero-maintenance drive and lube-free hanger system.

See the video at right for all the details...

SWECO Centrifugal Sifters employ centrifugal force generated by beater bars to propel material against the interior of a cylindrical screen. Achieving forces many times that of gravity alone, these units deliver exceptionally high capacity in a small footprint.

SWECO Turbo-Screens use high velocity air to convey feed material to a screen and to drive fine particles through the screen. The result is especially high capacities through relatively fine screens.